Jumping Car Information

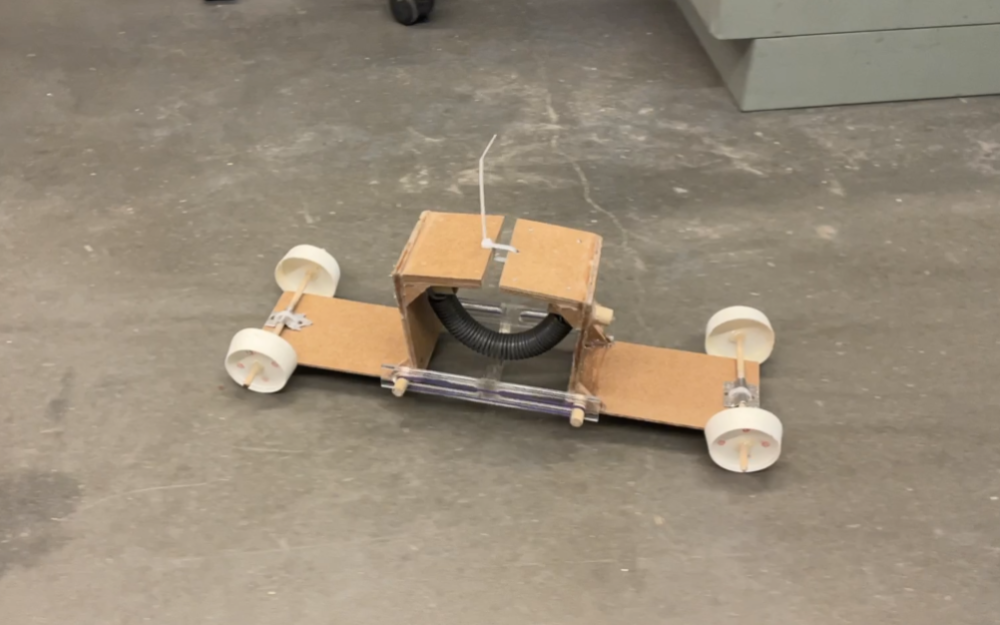

The purpose of the project was to determine the feasibility of a car that can jump between 20-40 cm vertically. The main functions that define the car are jumping and moving around, while other functions include receiving and executing signals, powering itself, withstanding landings, returning upright, and reloading the jump mechanism.

The prototypes of the toy prove the functionality of the jumping mechanism and reloading mechanism; however, they do not prove the viability of the other defined functions. We decided to deeply explore two difficult functions to gain more robust experience with prototyping, analysis, validation, and making changes.

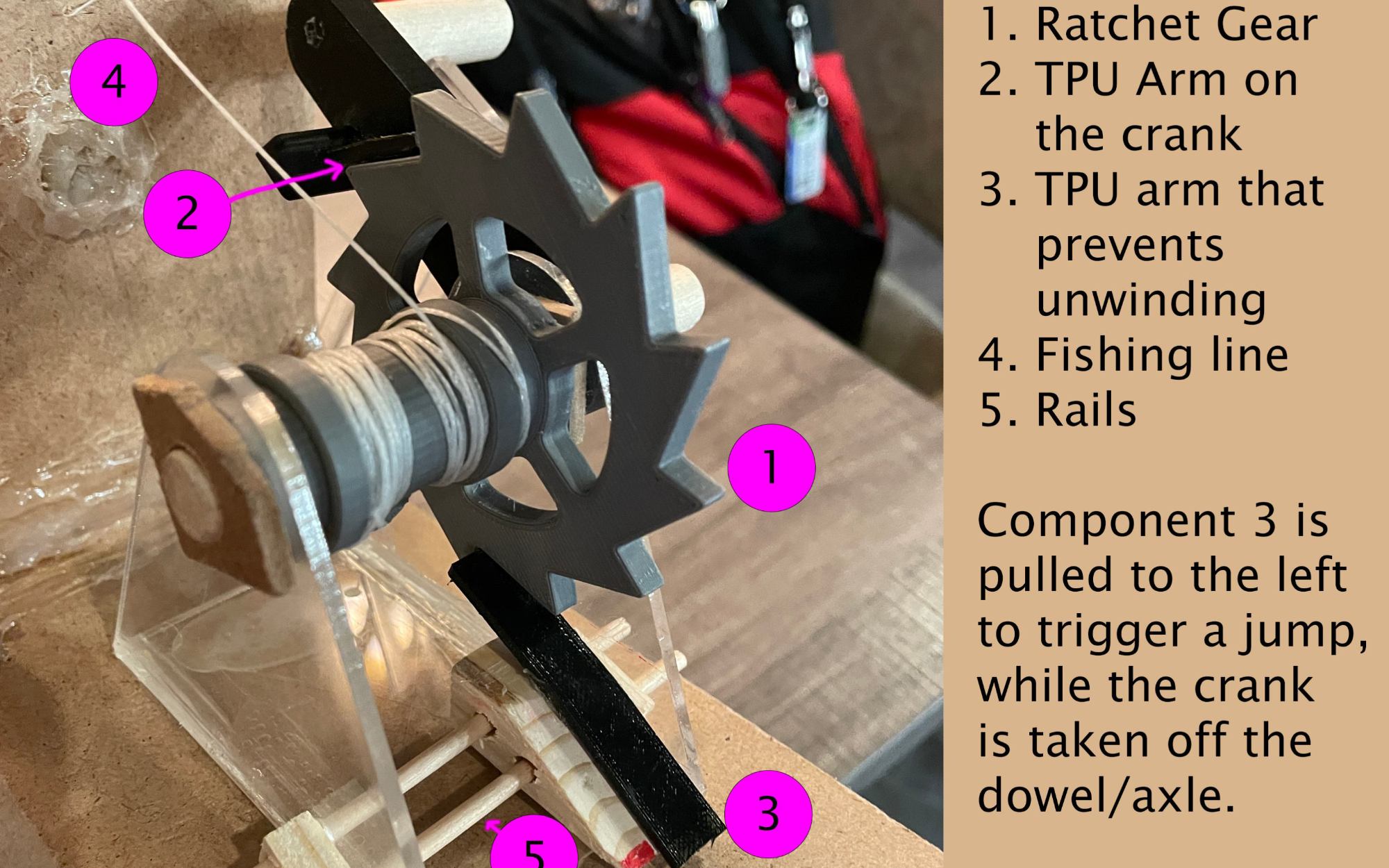

During the project, I devised a mechanism that uses a ratchet gear with a pawl to wind up a string for a user-commanded jump. As shown in Image 2, it uses a 3D-printed custom ratchet gear that I designed in SolidWorks, along with two 3D-printed flexible-TPU arms. A crank attached to a TPU arm lets the user push the gear in one direction to wind up a string, while the second TPU arm prevents the ratchet gear from unwinding.

Both arms need to be moved away to trigger a jump; this mechanism rapidly and easily prepares the car for a jump, but poses safety hazards due to user proximity. To partly mitigate these hazards, I added rails that the TPU arms can move along, as indicated in Image 2. A 6-ft string allows the user to pull the TPU arm and the crank away from the ratchet gear to trigger the jump from a distance.

When the spring is wound, the two halves of the car frame are pulled together, thereby bending the spring. I used AutoCAD to design and laser cut the transparent acrylic rails along with the HDF frame. While designing the components, I had to ensure that the spring, string, and wheels could be integrated; the frame also had to handle the force of a 70 N spring, which was powerful enough to launch the 700g car 40 cm upwards. Ribs and the choice of HDF make the car sufficiently durable.

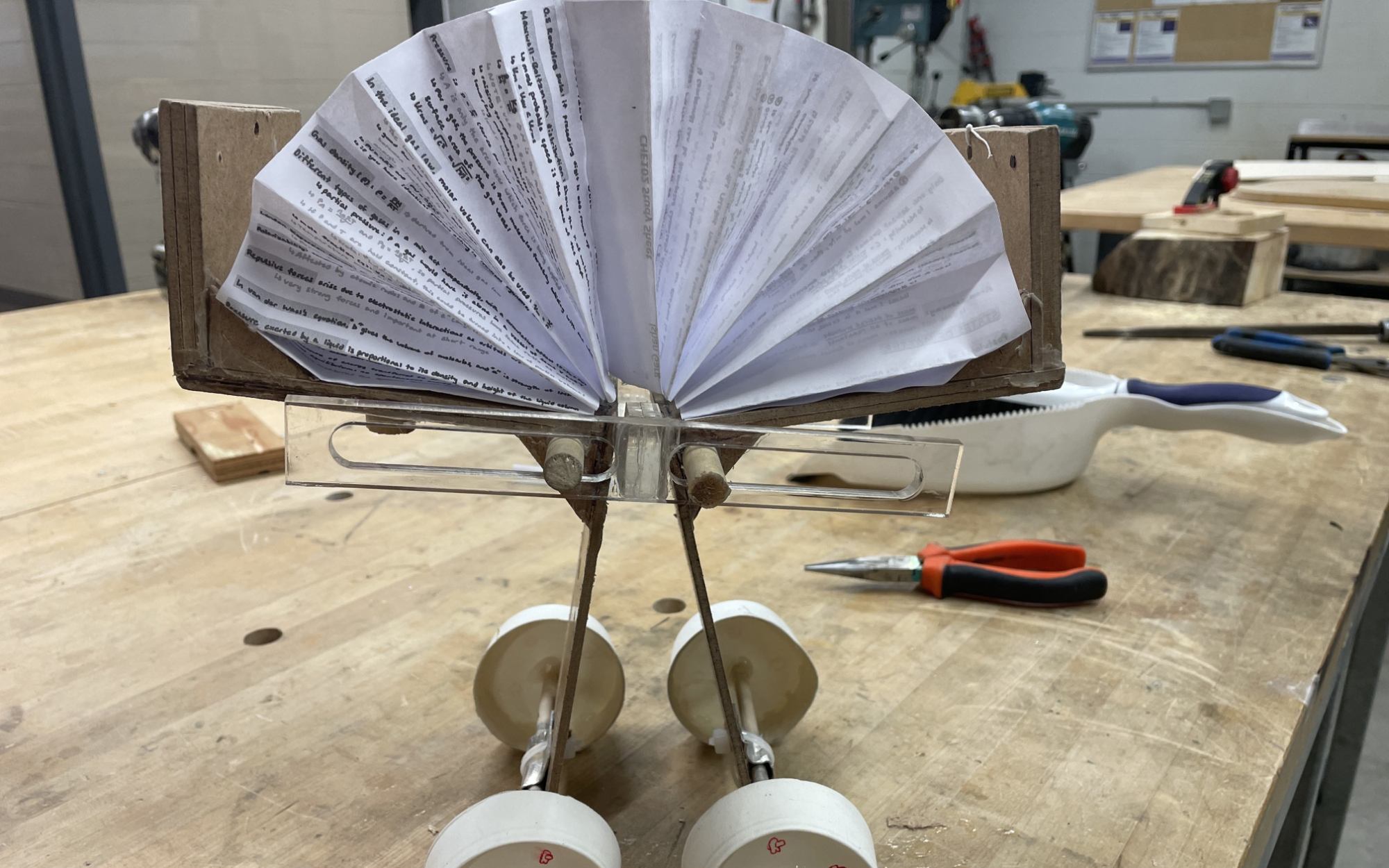

In a technical report on the project, I documented over 10 solutions that were considered for the jumping and release mechanisms, including compressed air, elastic bands, springs, TPU ratchet arms, and PLA arms, to name a few. I also documented all safety hazards, which include pinch points, stored energy, and fast-moving parts. I designed an accordion-like paper cover for the jumping car, as shown in Image 3, to limit exposure of the spring for user safety.

Material selection posed a challenge during the project. The frame and wind-up string had to withstand the force of a 70 N spring and a 40 cm drop. We compared plastic thread versus 100-lb fishing line for the string, and high density fiberboard (HDF) versus acrylic for the frame. We chose fishing line due to its high abrasive resistance and tensile strength, and HDF due to its flexibility.

That fishing line is used to pull the two halves of the frame together and consequently bend the spring; however, a problem is providing enough torque to pull the line. I solved the challenge by devising the winch-like mechanism that employs a ratchet gear.

Some further challenges to solve include integrating an electronic jump release mechanism, a gearbox to make the car drivable, and an exterior that is more aesthetically pleasing and does a better job at keeping the user safe.